Product Technology

Product Introduction

Bio & Environment (including semiconductor cleaning)

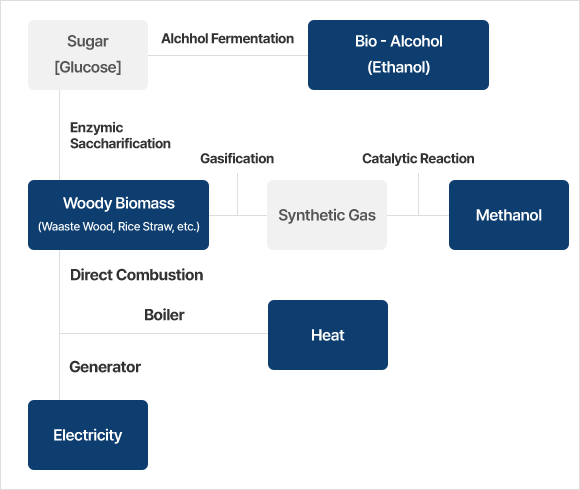

Biomass (STRAW, PLANTS, CORN STOVER, WOOD PULP, SUGAR CANE, WOOD CHIPS, GRASSES, FIBERS)is a carbon-neutral eco-friendly energy source,

that emits very little SOx, NOx, and carbon dioxide when burned, and is in the spotlight as a renewable power generation fuel.

Among them, wood pellets are manufactured with a constant quality within 10% moisture content and can be supplied with stable calories of more than

4,000 kcal/kg.

-

University-S (pyrolysis)

University-S (pyrolysis)- • Operation :

-

Biomass pyrolysis reaction.

- • Experimental conditions :

-

- Components suitable for high temperature

(up to 800'C) must be provided / the STIRRING UNIT is specially designed for mixing at high temperatures, Select a special material suitable for high temperature, HEATING OVER TEMP. CONTROL POINT is provided for researchers to use safely.

-

University- H (environment)

University- H (environment)- • Operation :

- Test device for air pollution reduction substance development / Device for airfilter dust efficiency improvement and measurement.

- • Experimental conditions :

-

- Closed structure and airflow control points.

- Visibility and program linkage are the key points.

- Designed to meet moisture-proof and dust-proof specifications.

- It is possible control FAN SPEED.

-

University- H (environment)

University- H (environment)- • Operation :

-

Test device for air pollution reduction substance development / Device for airfilter dust efficiency improvement and measurement.

- • Experimental conditions :

-

- Closed structure and airflow control points.

- Visibility and program linkage are the key points.

- Designed to meet moisture-proof and dust-proof specifications.

- It is possible control FAN SPEED.

-

University- H (environment)

University- H (environment)- • Operation :

- Test equipment for air cleanliness.

- • Experimental conditions :

-

- Closed structure and airflow control.

- Visibility and linkage of program are the key point.

- Made to meet moisture-proof and dust-proof specifications.

-

Company Research Institute-E (environment)

Company Research Institute-E (environment)- • Operation :

- A device for developing bead activated carbon with low abrasion and high efficiency that absorbs VOCs or odors.

- • Experimental conditions :

-

- The special material and design are reflected so that the TUBE can rotate at high temperature (MAX.1000℃), since mixing must be done smoothly in a horizontal high-temperature reactor, the selection and design of suitable parts are important.

- Add technical skills so that the beads do not clump together evenly.

-

University- H (environment)

University- H (environment)- • Operation :

- A device for developing bead activated carbon with low abrasion

and high efficiency that absorbs VOCs or odors.

- • Experimental conditions :

-

- At high temperature (MAX. 300℃), high accuracy of simulated gas injection control is important.

- Add technical skills so that the beads do not clump together.

-

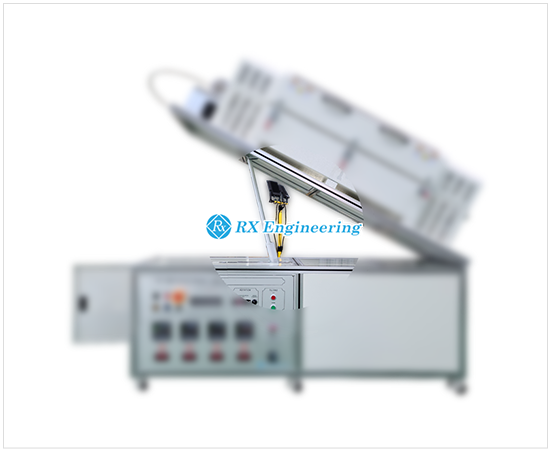

Company Research Institute-E (environment)

Company Research Institute-E (environment)- • Operation :

- Development of photocatalysts and beads capable of air purification, deodorization, removal of harmful substances, food poisoning prevention, anti-fungus, disease infection prevention, antibacterial, sterilization.

- • Experimental conditions :

-

- High temperature (MAX. 900℃), full rotation and tilting of the tube reactor are possible.

- Add technical skills so that the beads do not clump together.

-

Company Research Institute- H (For study on the

Company Research Institute- H (For study on the

treatment of cleaning an exhaust gas in

semi-conductors)- • Operation :

- To remove toxic industrial chemicals (TICs).

- • Experimental conditions :

-

- TICs Absorption and desorption performance and efficiency evaluation equipment.

- It consists of multiple channels because it is for analysis by peeling schema.